Draft beer, also known as draft beer, is a kind of aseptic filtered and aseptic filling beer without pasteurization or high temperature instantaneous disinfection. It contains rich amino acids, carbohydrates, inorganic salts, a variety of vitamins and a variety of active enzymes, which can enhance appetite and promote digestion

Draft beer belongs to the high class of beer. Filtration and sterilization is the key link of production. Membrane separation technology can completely retain all kinds of nutrients in food by using the screening principle. When applied to the production of draft beer, the liquor produced is more clear and transparent, the bubble retention is longer, and the sensitive protein and cold turbidity index are more than 30% lower than the filtration of the thousandaceous earth. However, the inevitable membrane pollution seriously affects the filtration performance, and the stable equilibrium pass layer is only about 10L/(m²/h), which limits the application of membrane filtration technology in beer production.

Draft beer belongs to the high class of beer. Filtration and sterilization is the key link of production. Membrane separation technology can completely retain all kinds of nutrients in food by using the screening principle. When applied to the production of draft beer, the liquor produced is more clear and transparent, the bubble retention is longer, and the sensitive protein and cold turbidity index are more than 30% lower than the filtration of the thousandaceous earth. However, the inevitable membrane pollution seriously affects the filtration performance, and the stable equilibrium pass layer is only about 10L/(m²/h), which limits the application of membrane filtration technology in beer production.

The experimental method

The pore size distribution of PVDF membrane was determined by self-made bubble point – velocity method pore size distribution tester. The circular diaphragm is cut off from the dry film, soaked in a thousand of soaking liquid until translucent, removed and dried with filter paper, and then spread on the detector for detection. The soaking solution was isopropanol, and the pressure source was nitrogen.

For contact Angle measurement, a 2cmx2cm square diaphragm was cut, fixed on the slide, and placed on the sample table for detection. The contact Angle of water droplets from the surface of the film to completely disappear was recorded.

The upper and lower surfaces of the representative film samples were attached to the sample table with conductive adhesive respectively. The cross sections were frozen and quenched with liquid nitrogen, and the cross sections were attached to the sample table with conductive adhesive. The samples were locked in vacuum and placed on the electron microscope platform for observation.

Microbial count E. coli count: Take the sample to be tested, refer to GB4789.3-2010 for testing. Total colony count of draft beer: Draft beer samples were taken before and after filtration and tested according to GB4789.2-2010. Yeast count: Take draft beer samples before and after filtration, refer to GB4789.15

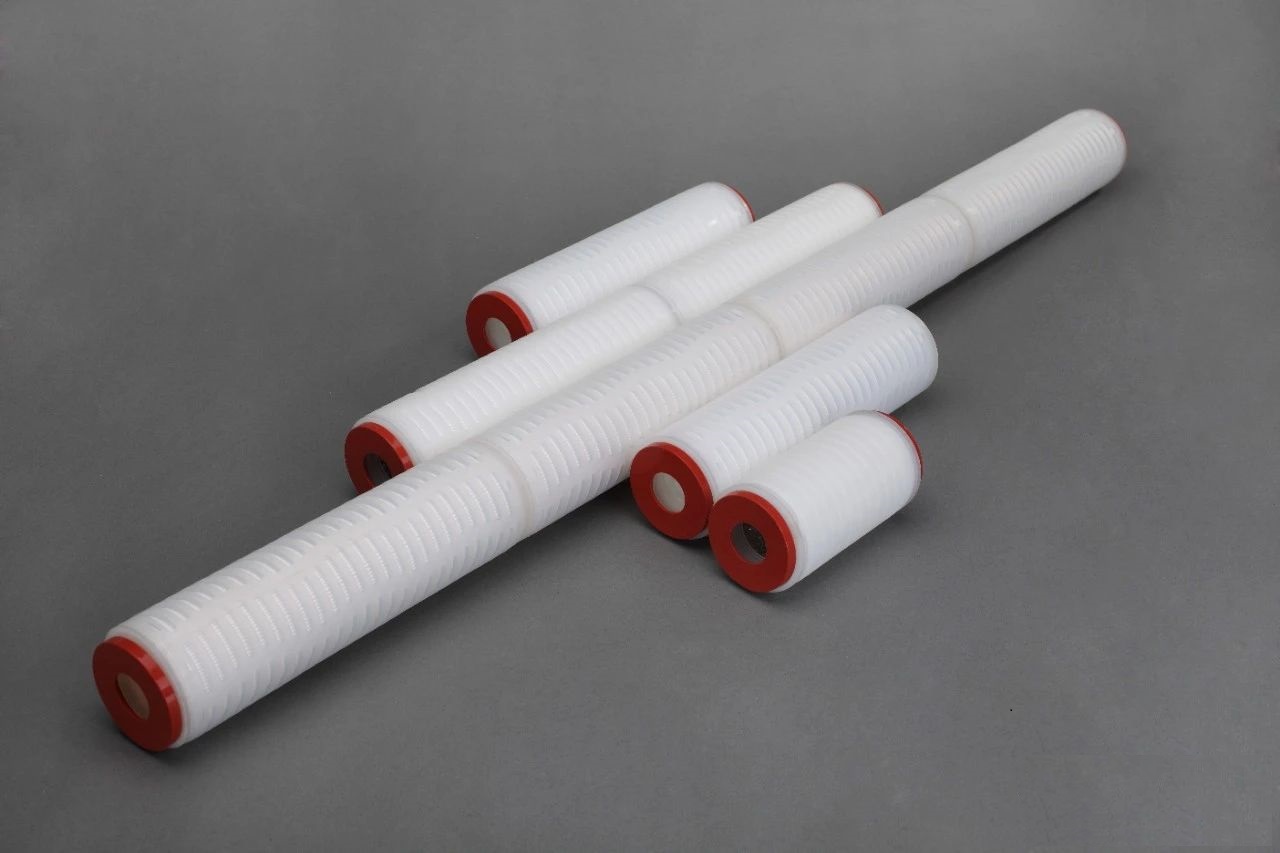

The hydrophilic pvdf-n or pvdf-f microfiltration membrane was put into the membrane pool and sterilized by 121°C high-pressure steam for 20min. A self-made filter device (see Figure 1) was used to measure the variation of draft beer filtration flow with filtration time under lOOkPa filtration repulsion force, and the experimental process was shown in Figure 2. The first filtration process of the new membrane is denoted as C. After filtering for a period of time until the membrane flux attenuation reached a stable value, the membrane was cleaned to recover the membrane flux, and the cleaned membrane was continued to filter draft beer. The first four cycles of membrane cleaning were washed with water, and the last four cycles were washed with 0.05mo1/L NaOH solution, 0.05mo1/L HCl solution and water alternately.

Post time: Sep-15-2022